Since 1978 we’ve cut & sewn for the best. What’s your challenge? Call 800-673-6341 with your fabric fabrication project.

Since 1978 we’ve cut & sewn for the best. What’s your challenge? Call 800-673-6341 with your fabric fabrication project.

- Company: (A Body Armor Company)

Time Frame: October 2001 to Present

Products: OTV, IOTV Body Armor Outer Vest Ensemble

Production Volume: 1,100,000 Units - Company: (A Body Armor Company)

Time Frame: March 2003 to Present

Products: OTV, IOTV Body Armor Outer Vest, Tactical assault Panels

ELCS Kit, Spear Vest

Production Volume: 390,000 Units - Company: (A Body Armor/ Tactical Equipment Company)

Time Frame: November 2003 to Present

Products: Outer Vest for Body Armor, Assault Packs, Cases, Bags,

Pouches

Product Volume: 425,000 Units - Company: (An Assault Pack Company)

Time Frame: May 2004 to Present

Products: Navy Seal Assault Packs

Production Volume: 2,000 Units - Company: (A Body Armor Company)

Time Frame: September 2009 to Present

Products: IOTV Outer Vest

Production Volume: 110,000 Units - Company: (A Body Armor Company)

Time Frame: March 2007 to Present

Products: DHS Carry Bags

Production Volume: 20,300 Units - Company: Tumi, Inc. – Middlesex, New Jersey

Time Frame: June 1982 to March 2002

Products: Luggage

Production Volume: 2,500,000 Units

At Your Service

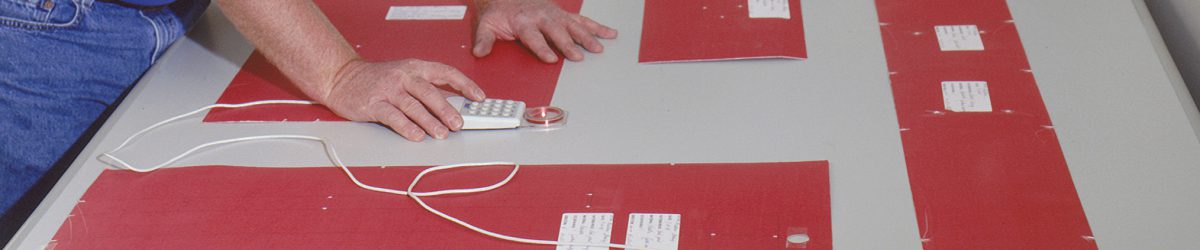

- Cutting Room

- Gerber Accu -Mark Pattern Grading and Marker-Making System

- 2 Gerber System Computerized Cutting Machines

- Standard knife cutting

- Die Cutting – 20″ X 40″ clickers and 40″ X 68″ beam press

- Hot/Cold Strip Cutting

- Slitting equipment

- Shearing equipment

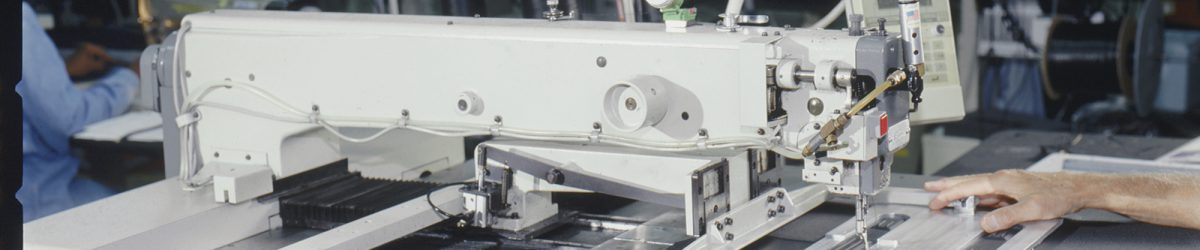

- Sewing machines

- full feature electronic single needle, double needle, long arm, cylinder arm, bar tackers—programmable – heavy, medium, and light duty – 700 machines in total.

- Complete leather working equipment

- Stamping/embossing

- Riveting & grommet equipment

- Embroidery/screen printing

- Product assembly, warehousing, shipping

Technical Service Capabilities

- Full staff of GSD-certified industrial engineers

- New Product Development Department

- New Product Manager – 20 years of experience in the development of sophisticated lines of military gear, sewn/fabricated industrial products, and consumer products.

- Sample Shop – we have complete capabilities to produce finished samples of any military gear, sewn/fabricated industrial products, or consumer products.

- Fully-equipped mechanical shop capable of designing and manufacturing equipment, labor-saving devices, work aids, tacker clamps, etc.

Production Facilities and Capabilities

- Three state-of-the-art plants in South Georgia employing highly skilled sewing machine operators, in addition to other related production workers.

- 140,000 sq ft of manufacturing space

- Complete in-line statistical Quality Assurance Program.

- Computerized scheduling

- Vestibule Training Program staffed with Training Supervisors and instructors

Human Capital

- All SLW associates undergo extensive orientation and job- skills training and are tracked with an on-the-floor 4 – 16 week training curve program.

- All SLW associates undergo continuous quality assurance, safety and new-product training.

Experience on site, fully engaged management with a highly trained and motivated workforce.